6th Face refers to the face opposite the main machined face of a part.

For example, in a Door the main face (1st face) may be the front of the door with a routed design. The 6th face being the back of the door, where the hinges are mounted. The reason it is the 6th face is that the four edges of the door are faces 2 to 5. So when processed on a flatbed, the part has to be turned over to machine both its 1st and 6th faces.

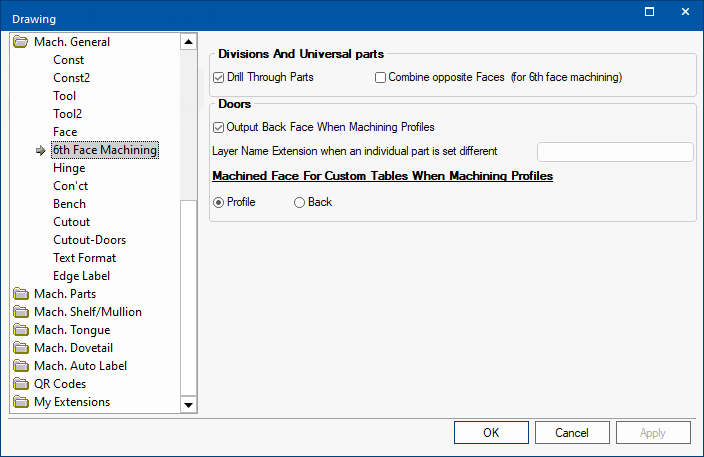

The Mach.General > 6th Face Machining page in the Catalog/Drawing Properties allows you to enable 6th face machining.

Turn on the Combine opposite Faces option checkbox to enable 6th face machining on divisions and universal parts.

Turn on Output Back Face When Machining Profiles option checkbox when machining profile doors and drawer fronts which will allow you to output both faces to machining.

When machining both faces of doors, you can specify which side of the door to apply custom machining tables to.

Select one of the options using the radio buttons i.e.