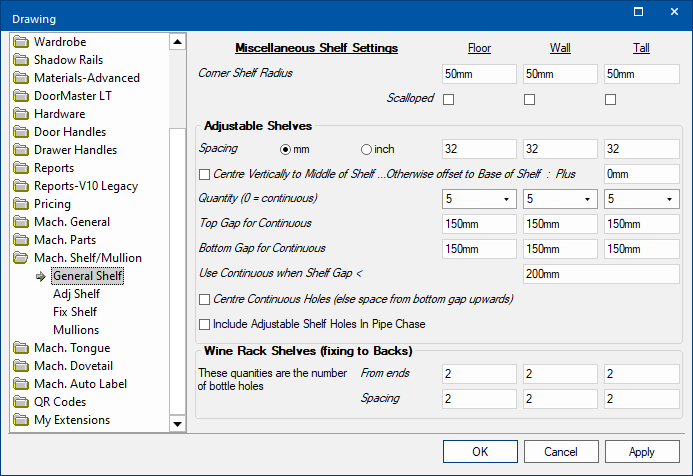

The Mach.Shelf/Mullion > General Shelf page of the Catalog/Drawing Properties defines general settings on the use of adjustable shelf holes (in Ends and Backs) and the shelf internal radius.

These setting can be different for each of the cabinet types i.e. Floor, Wall and Tall.

When any internal corner is cut using a flatbed router, it will always leave a rounded corner. If this is to be anything different from the radius of the tool, then it is specified here.

Adjustable shelf holes can either be a continuous over the height of the cabinet or grouped at the appropriate point for each shelf.

Spacing

Spacing is the distance between the centre of each adjustable shelf hole. A number, rather than a length entry (e.g. 32 rather than 32mm), is required as this allows for more accurate entry (especially when imperial measurements are being used).

Machines with drill banks have tools set at a precise distance apart (usually 32mm). If the conversion of imperial measurements to decimals does not exactly cover to this 32mm then the drill bank is not used as the holes are perceived to be the wrong distance apart.Quantity

Quantity is the number of shelf holes in each shelf ‘grouping’. If this is set to zero then continuous shelf holes will be used. As well as being set here, each cabinet has an option to change the grouping.

Top/Bottom Gap

This is the gap between the bottom of the component on which the holes are being made, to the first continuous hole. It is also used as the minimum gap between the last continuous hole and the top.

When there are many shelves in a cabinet, the groups of adjustable shelf holes can overlap. In these cases it is possible for the cabinet to automatically revert to the use of continuous holes. Cabinets with any one shelf gap less than the specified distance will do this.

Centre Continuous Holes

The continuous shelf holes could either be centered or based on a starting distance from the bottom of the interior space. When 'Centre' is selected, these will also respond to the offset.

At Cabinet level, the shelves in Parts, Robes and Universals have the ability to have any number (minimum of 2) of columns of shelf hole supports in their Ends and Divisions.

Example : Universal

Cabinet Machining > Shelf Adj options to Set Quantity (in Ends) and Offset

Example : Part

Part Machining > Adj Holes option to Set Quantity (in Ends)

Include Adjustable Shelf Holes in Pipe Chase

Enable by ticking the check box to include adjustable shelf holes in the pipe chase.

At Cabinet level this option is available on the Labour & Construction > Pipe Chase page.

Labour & Construction > Include

Wine rack shelves are assumed to be Fixed Shelves, but the positioning of the fixings is based on the bottle holes. So the quantities here are the number of bottle holes (not lengths as elsewhere). This is because the shelves and divisions are made to interlock and the fixing of shelves to the back should be done at the centre of a bottle hole.

A minimum of two (2) fixings are used (one at each end). These setting can be different for each of the cabinet types i.e. Floor, Wall and Tall.

The From Ends setting is the distance (number of bottle holes) from each end that these first two (2) fixings are placed.

The Spacing is the distance (number of bottle holes) from the first two fixings, that subsequent fixings are placed. These subsequent fixings are calculated separately from each end moving towards the centre. So, it is possible to get a doubling up or an odd spacing at the centre.