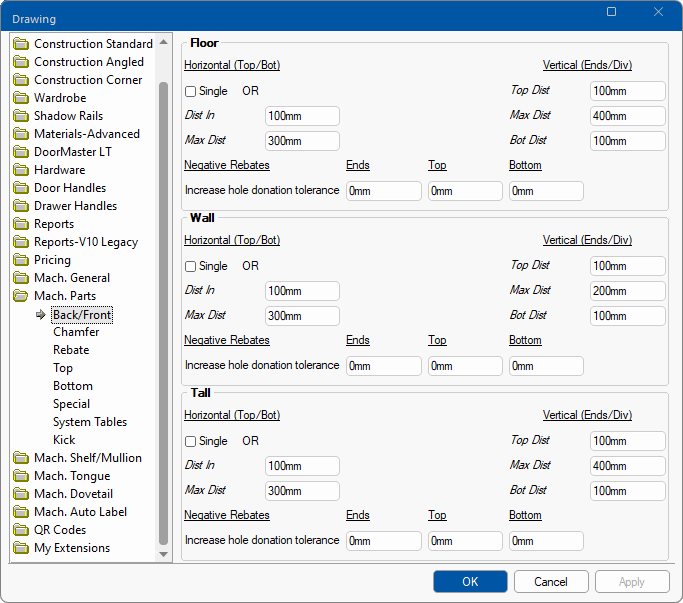

The Mach.Parts > Back/Front page of the Catalog/Drawing Properties defines how backs and fronts, when applicable, are secured on horizontally and vertically.

Three (3) sets of variables are used, one each for FLOOR, WALL and TALL cabinets. The settings and associated variables are :-

For fixing of both Tops and Bottoms to Backs. The quantity of fixings is determined by the width of the back.

Enable a Single fixing point at the centre, by ticking the checkbox OR two fixings, one at each end, are placed at the given distance from the end.

Further fixings are then added as the width increases based on the maximum distance apart.

This currently only applies to ‘standard’ (rectangular) cabinets and not to chamfered backs.For example, using the settings below, if the width of the back was 600mm, then three fixings would be used :

- one at 100mm from each end

- then one in the middle as the distance between the end fixings (400mm) exceeds the 300mm maximum.

For fixing Ends to Backs or Backs to Backs in corner units. The quantity of fixings is determined by the height of the back.

Two fixings are placed, one at each end, at the given distance from the top and bottom.

Further fixings are then added as the width increases based on the maximum distance apart.

If a Back Rebate is set to a negative value on the Construction Standard > Backs page, then parts may not touch each other causing construction holes not to appear. To overcome this, values can be set to provide extra depth tolerance on construction holes.

Values entered here will be reflected on the Construction Standard > Backs page and visa versa.

When a Back is 'Between the Ends' the Back donates construction holes (e.g. for screws) into the End. Within the machining for this is a property that dictates how far away the Back can be from the End before the donation ceases. The default for this is 1mm. So, if the back is pulled away from the End by more than this the donation does not occur. A negative rebate will shrink the Back away from the End, which some customers like to do to allow some 'wiggle room' as materials are not always their advertised thickness. At the same time they still want to screw them together.