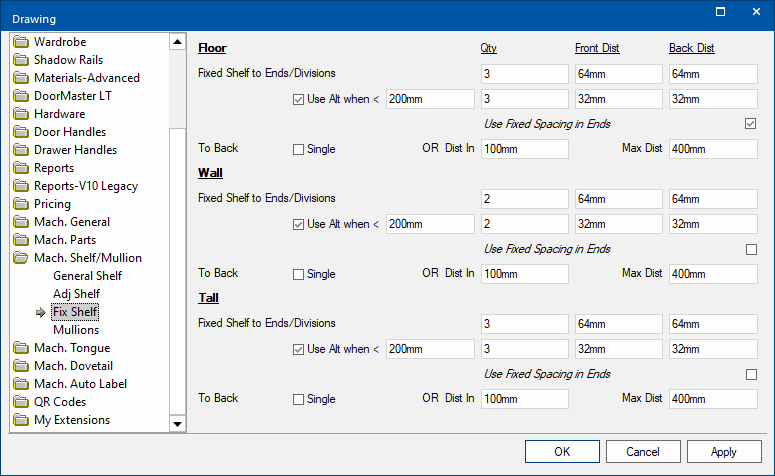

The Mach.Shelf/Mullion > Fix Shelf page of the Catalog/Drawing Properties provides settings that effect the presence and positioning of fixings for shelves in Ends and Backs and can be different for each of the cabinet types (Floor, Wall and Tall).

Different settings are available for the different Cabinet Types i.e. Floor, Wall and Tall.

If the Fixed Shelves are to be held on by screws, then there are two (2) methods of manufacture. However, any other fixings just use the first method.

Method 1

For each cabinet type, a quantity of fixings can be defined with a minimum of two fixings used.

The first two (2) are placed at the selected distance from the ‘Front’ (of the Shelf), with the remained equally spaced in-between.

If the Use Alt when check box in ticked and the ‘Shelf’ is narrower than the Size specified, then the alternate set of values are used instead of the above.

Method 2

Only available when screwed together.

Up to four (4) screws can be used and their positions are fixed based on the distance from the front. This option is useful if the Shelves are to be End drilled on a separate machine with fixed holes spacing.

When the Use Fixed Spacing in Ends check box is ticked, an additional page Mach.Parts > Ends page is made available. This option also allows for up to (2) two locating dowels to be drilled of a different size and depth.

Fixed shelves are attached to Backs. The quantity of fixings controlled by the width of the back and the chosen spacing (a minimum of 2 fixings are used).

Dist In is the distance between the two (2) end fixings and the end of the back.

Max Dist then controls the maximum distance that the two fixings can be apart.

For settings for shelves in chamfered backs see Mach.Parts > Chamfer page.

The ability to use just one fixing point on the back of shelves. This one fixing point being the middle of the shelf.

This feature only operates on rectangular shelves and not shelves on Corner or Angled Cabinets.