Drawer fronts of a single drawer cabinet can be combined into a single drawerbank, which will hold them in a block to preserve the pattern of the grain.

The first thing you need to do is, in the Drawing Properties, specify that you are requiring Drawer Fronts to set as a drawer bank.

On the Materials-Advanced > Drawer Bank page there is an option to Use Full Door for Drawer Fronts.

This option makes the drawers on a single cabinet become a complete door with recut values to break into separate parts. This recutting can now be completed with a CNC router bit, or a Panel Saw manually.

We will now discuss how to do each method.

CabMaster Pro, or CL users with the ability to create a board report will need to change the value of the Saw blade thickness to the value of the Panel Saw blade thickness.

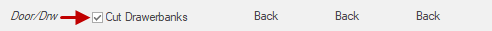

This can be done in the Catalog/Drawing Properties on the Construction Standard > Doors/Fronts page under the Drawer Bank group box.

Result

The Drawer bank will be reported as the total of each drawer size, plus Xmm between each drawer, where X is the thickness of the saw blade thickness.

This method is for CabMaster Machining Premium customers wanting to Cut the Drawer bank on the CNC and then recut the drawers manually with a Panel Saw.

Result

The CNC will cutout the entire door which is each drawer size, plus Xmm between each drawer, where X is the thickness of the saw blade thickness, which will then need to be put through the Panel saw to break into individual fronts.

This method is for CabMaster Machining Premium customers wanting to completely cut the Drawer bank and the recuts on the CNC.

Result

The CNC will cutout the entire door, and recut it into individual pieces.