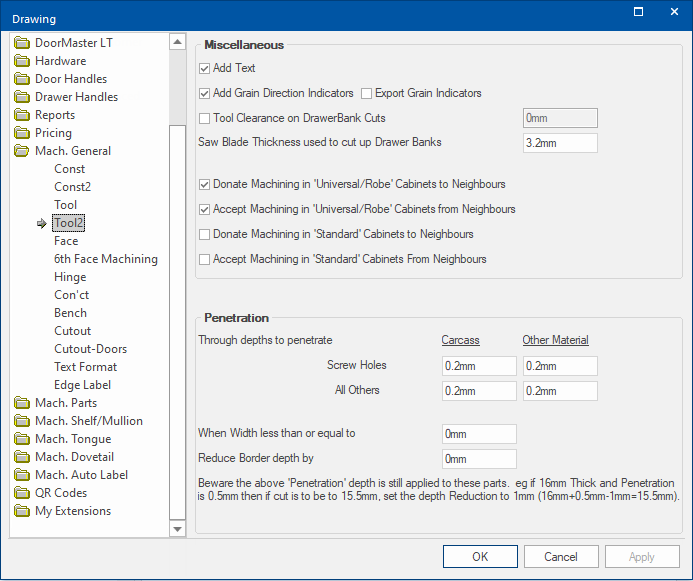

The Mach.General > Tool2 page in the Catalog/Drawing Properties is used to set tool clearance on DrawerBank Cuts and control penetration of screw holes through material separately from other layers.

To locate information about any option on the following image,  click on the area of interest.

click on the area of interest.

Enabling this option allows the descriptive text to be added to machined parts.

Example:

See Mach.General > Text Format page.

If enabled and a grained material has been selected, arrows will show the direction of the grain. These are indicators only, to assist with understanding current grain direction, and do not get machined.

Enabling this will export the grain indicator arrows as part of the machining.

If a drawerbank is cut on the machine, checking this option will allow you to specify a length for tool clearance.

Allows you to specify the saw blade thickness used to cut up Drawer Banks and is the same as the option on the Construction Standard > Doors/Fronts page.

Turn off/on 'Universal/Robe' Cabinets to/from Neighbours using check boxes.

Turn off/on 'Standard' Cabinets to/from Neighbours using check boxes.

Within cabinets, the parts that touch each other, donate machining to each other (such as construction holes).

For example where an End butts into the Back, the End will 'donate' the construction holes it needs into the Back (the Back will then 'accept' these holes). The same thing can occur between cabinets (for example, the Back from one cabinet may butt into the End of another).

This however, is not always desirable and so can be turned on and off using these settings.

These options control the Drill Through and Opposite Face DXF for Universals/Robes on the Cabinet Machining > Machining page.

These options control penetration of screw holes through material separately from other layers.

Penetration will only be applied When Width less than or equal to the value stated in the edit box.

Allows you to Reduce Border depth by the value stated in the edit box. See example above.