This topic discusses the Cabinet Machining category for the following...

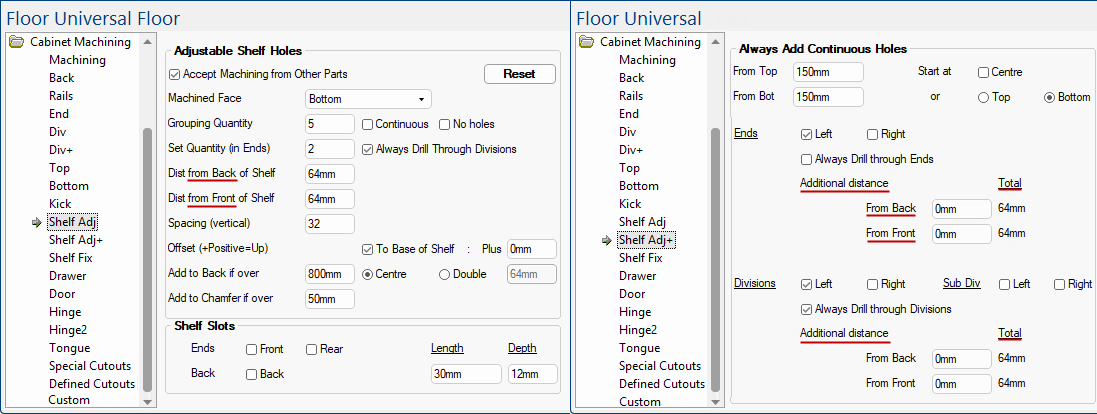

Within cabinets, the parts that touch each other, donate machining to each other (such as construction holes). However, is not always desirable and can be turned on and off using this checkbox.

For more on Donate/Accept Machining, see Mach.General > Tool2 page of the Catalog/Drawing Properties.

If a division has adjoining parts on both faces, checking the Always Drill Through Divisions option will drill all holes for the adjoining parts for both faces, but they will all be drilled through the material.

The Shelf Adj page options are used to determine if holes are required, the number and spacing of machined holes.

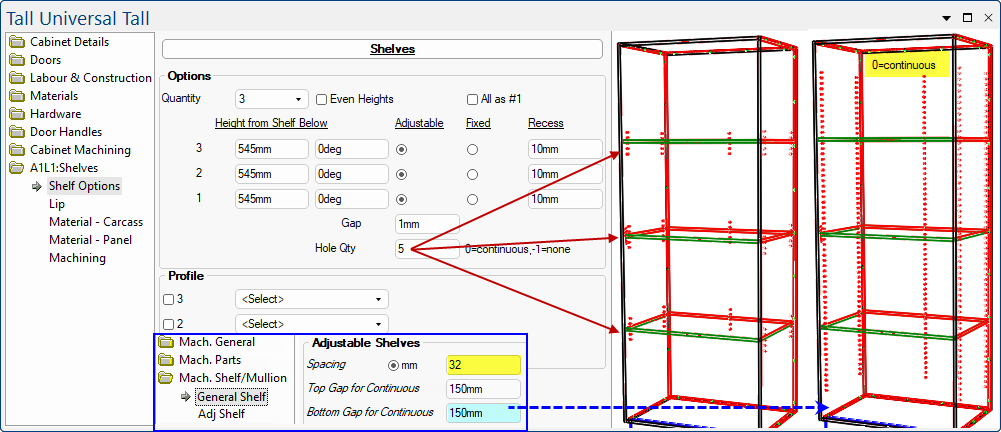

For the End panels in these examples, the Spacing of vertical holes is 32mm (highlighted in blue) and the Offset options are illustrated in yellow.

The Set Quantity (in Ends) is set to 2 and are

If Holes are required, then you can choose...

- a Grouping Quantity : e.g. is set to '5' (see example below left).

- which corresponds to the Hole Qty option on the Shelf Options page.

- Continuous : if enabled would have continuous holes drilled 32mm apart (see example below right).

- the corresponding Hole Qty option on the Shelf Options page would be set to '0'

The Shelf Adj+ page options are used to adjust the Top/Bottom gap when holes are continuous.

Defaults are set on the Mach.Shelf/Mullion > General Shelf page of the Drawing Properties, shown below inset.

Shelf Slots are a machine line that can be set up in EzyNest, using a bullnose or an endmill tool, to cut a slot in the bottom of the shelf that sits over the shelf pin.

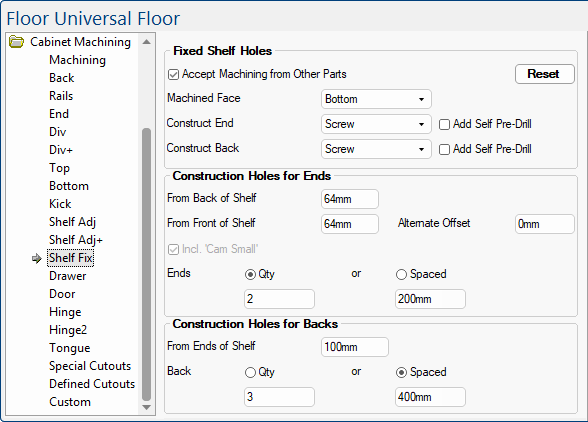

Add Self Pre-Drill default can be set on the Mach.General > Tool page of the Drawing Properties but is only applicable to Screw Construction.

The settings for construction holes are set on the Mach.Shelf/Mullion > Fix Shelf page of the Drawing Properties.